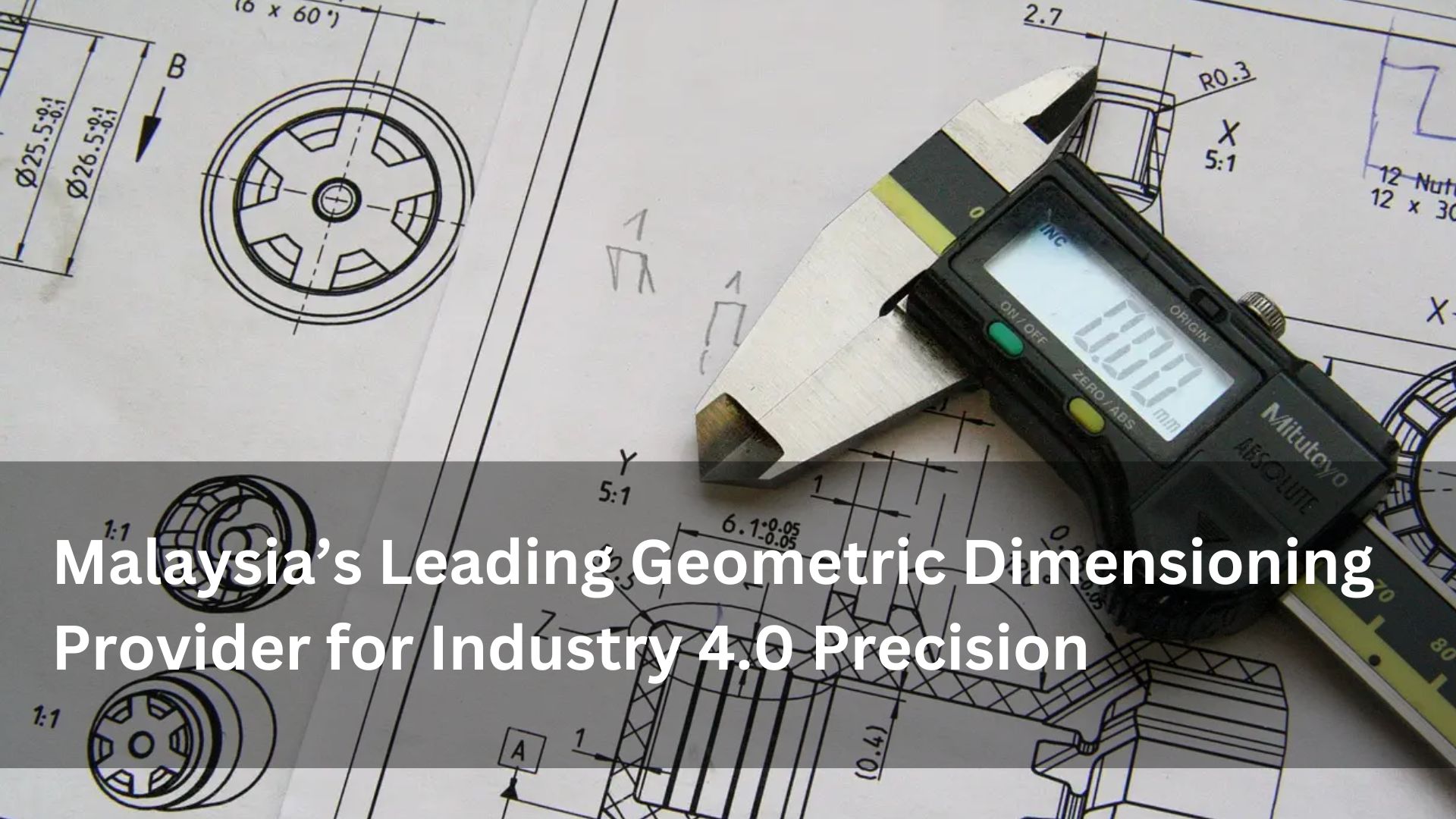

As Malaysia accelerates into Industry 4.0, the demand for precise and efficient design and manufacturing methods is rising. Central to this transformation is the application of Geometric Dimensioning and Tolerancing (GD&T)—a global standard for defining engineering tolerances. To keep pace with technological change, manufacturers, designers, and quality engineers are turning to a reliable Geometric Dimensioning Provider Malaysia to ensure consistent, efficient, and compliant operations.

This article explores how geometric dimensioning supports product integrity and performance, why choosing the right provider matters, and the benefits of integrating GD&T training and consulting into your engineering workflow.

Why Choose a Geometric Dimensioning Provider Malaysia?

Choosing a local Geometric Dimensioning Provider Malaysia ensures:

Contextual understanding of local industries and compliance needs

Tailored training solutions for automotive, aerospace, semiconductor, and tooling sectors

Affordable services with no need for overseas instructors

Flexible delivery through online, in-house, or hybrid sessions

Working with a domestic provider ensures faster implementation, culturally relevant communication, and support in local languages when needed.

Services Offered by a Geometric Dimensioning Provider Malaysia

An experienced Geometric Dimensioning Provider Malaysia typically offers:

Foundational GD&T Training: Introduction to symbols, rules, and frameworks

Advanced GD&T Courses: Functional dimensioning, datum selection, and tolerance stack-up analysis

Engineering Drawing Review Services: Consulting for optimizing technical drawings

On-Site & Remote Training: Corporate packages for engineers, machinists, and QC teams

Certification Exams: Formal assessments to validate skill levels

These services are suitable for new learners, experienced engineers, and organizations transitioning to model-based environments.

Industry Applications of Geometric Dimensioning in Malaysia

A professional Geometric Dimensioning Provider Malaysia supports diverse industries, including:

Automotive: Ensuring alignment of engine, body, and chassis components

Aerospace: Controlling tight tolerances in wing, landing gear, and turbine assembly

Oil & Gas: Assuring dimensional integrity of high-pressure equipment

Medical Devices: Maintaining strict tolerances in implants and surgical instruments

Consumer Electronics: Managing micro-part alignment in PCB assemblies

Training and implementation guidance from a certified provider ensures that parts meet function, fit, and form requirements.

How GD&T Improves Manufacturing Efficiency

Working with a Geometric Dimensioning Provider Malaysia can deliver tangible performance outcomes:

Fewer Drawing Interpretation Errors: Symbols convey intent precisely

Reduced Manufacturing Variability: Tolerances control process deviations

Improved Part Functionality: Align dimensions with real-world performance

Enhanced Inspection Accuracy: Coordinate Measuring Machines (CMMs) interpret symbols directly

Quicker Time to Market: Teams can resolve design disputes faster

Ultimately, this leads to lower production costs, better product quality, and stronger customer satisfaction.

Key Features of a Reliable Geometric Dimensioning Provider Malaysia

Not all providers are equal. A trusted Geometric Dimensioning Provider Malaysia should demonstrate:

Experienced Trainers: Background in engineering, manufacturing, or quality control

Industry Certification: Affiliation with ASME, ISO, or other standard organizations

Custom Curriculum: Flexible courseware aligned with client tools and products

Proven Results: Client case studies, ROI metrics, and post-training performance

Support Materials: Practice drawings, reference guides, and after-course help

These features ensure that your investment translates to real operational improvements.

Case Study: GD&T Integration in a Malaysian Aerospace Manufacturer

A Selangor-based aerospace component supplier collaborated with a Geometric Dimensioning Provider Malaysia to improve drawing clarity and reduce inspection bottlenecks. Over a six-month period:

100+ engineers received advanced GD&T training

Drawing revision errors fell by 35%

First-pass inspection rates improved by 40%

The client reported smoother audits, enhanced supplier communication, and reduced scrap rates.

Preparing for ISO Certification with GD&T

Achieving certifications like ISO 9001, AS9100, or IATF 16949 requires clear dimensional documentation. A Geometric Dimensioning Provider Malaysia supports businesses by:

Standardizing engineering drawings across departments

Training staff in tolerance specification and inspection techniques

Aligning measurement tools and QA processes with design standards

Assisting with documentation and audit readiness

GD&T plays a direct role in meeting compliance requirements and improving customer confidence.

Future-Proofing with Digital GD&T and Model-Based Definition

Malaysia’s manufacturing sector is steadily moving toward digitalization. A forward-thinking Geometric Dimensioning Provider Malaysia also provides training in:

Digital GD&T Integration: Embedding tolerances into 3D CAD models

Model-Based Definition (MBD): Eliminating 2D drawings for direct manufacturing use

Smart Manufacturing Compatibility: Enabling machine-readable dimensions

Training your team now ensures they’re ready to handle future workflows and technologies.

Conclusion

In today’s competitive industrial landscape, precision isn’t optional—it’s essential. Collaborating with a trusted Geometric Dimensioning Provider Malaysia empowers your business with the technical tools, confidence, and expertise to create better products, improve processes, and exceed customer expectations.

From foundational GD&T principles to advanced tolerance analysis, these providers support every step of your design-to-production lifecycle. Make the smart move. Elevate your technical standards today with a certified Geometric Dimensioning Provider Malaysia and stay ahead in an increasingly precise world.